Renewable Energy

Amorepacific Group continues to invest in renewable energy with the goal to increase power generated from renewable energy in the mid-to-long term. To this end, we make full use of unused spaces across our business sites in Korea and overseas to generate energy from solar panels and renewable sources.

RE100 Declaration

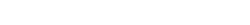

Amorepacific is the first in the Korean beauty industry to join the global RE100 initiative, which commits to sourcing 100% renewable electricity. Amorepacific is implementing a roadmap to convert 100% of electricity used at all business sites to renewable energy by 2025.

RE100 Implementation Road

RE100 Achievement Methods

We prioritize continuous energy reduction and efficiency improvement activities and are expanding self-generation facilities within business sites to produce and use renewable energy. Additionally, we secure renewable energy through various external procurement methods, such as direct and indirect PPA1), VPPA2), green premium tariffs, and certificate purchases. Through these efforts, we expanded Amorepacific's renewable electricity usage ratio to 51.4% in 2023.

1) PPA (Power Purchase Agreement)2) VPPA (Virtual Power Purchase Agreement)

-

Energy Reduction

and Efficiency Energy saving

Energy saving

and increasing

efficiency -

Expansion of Solar

Power Self-Generation Expansion of

Expansion of

self-generated

solar power -

Direct and Indirect

Renewable Energy Supply of renewable

Supply of renewable

electricity to

workplaces through

direct and indirect

renewable energy

purchase agreements -

Green Premium

Tariff Utilizing the

Utilizing the

Green Premium

Plan -

Renewable Energy

Certificates Purchasing

Purchasing

renewable energy

certificates

RE100 Achievement Methods

We prioritize continuous energy reduction and efficiency improvement activities and are expanding self-generation facilities within business sites to produce and use renewable energy. Additionally, we secure renewable energy through various external procurement methods, such as direct and indirect PPA1), VPPA2), green premium tariffs, and certificate purchases. Through these efforts, we expanded Amorepacific's renewable electricity usage ratio to 51.4% in 2023.

1) PPA (Power Purchase Agreement)2) VPPA (Virtual Power Purchase Agreement)

-

Energy Reduction

and Efficiency Energy saving

and increasing

efficiency

-

Expansion of Solar

Power Self-Generation Expansion of

self-generated

solar power

-

Direct and Indirect

Renewable Energy Supply of renewable

electricity to

workplaces through

direct and indirect

renewable energy

purchase agreements

-

Green Premium

Tariff Utilizing the

Green Premium

Plan

-

Renewable Energy

Certificates Purchasing

renewable energy

certificates